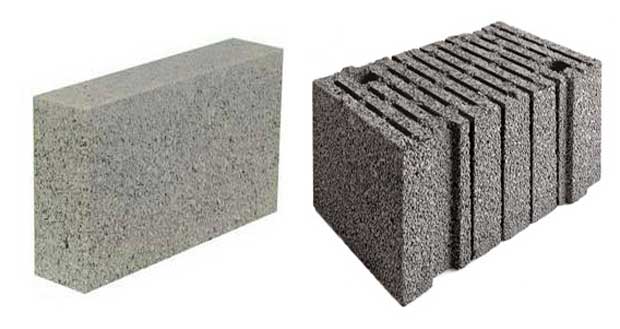

The bulk density of ordinary concrete is about 23 kN/m3. The concrete having bulk density between 5 to 18 kN/m3 is known as lightweight concrete and it is prepared from the following materials:

- Binding material: The ordinary Portland cement and its varieties can be used as binding material. If local binding material such as lime-slag, lime-cinder, etc. is available, the same can also be adopted as the binding material.

- Aggregates: For lightweight concrete, the loose porous materials are used as the aggregates. The natural porous aggregates can be obtained by crushing lightweight rocks. The artificial porous aggregates can be obtained from industrial wastes.

- Steel: The lightweight concrete is highly porous and hence it leads to the corrosion of reinforcement, if not properly protected. Hence, the lightweight concrete should be made adequately dense when used for R.C.C. work. Sometimes, the reinforcement is coated with anti-corrosive compounds, when lightweight concrete is adopted.

- Water: It is necessary to use pure drinking water to prepare lightweight concrete. The strength of lightweight concrete mainly depends on the amount of water in mix. The water-cement ratio for achieving optimum strength of lightweight concrete should be carefully worked out. As water content reaches to its optimum value, there is corresponding increase in the strength of lightweight concrete.

Advantages of lightweight concrete

Following are the advantages of lightweight concrete:

- The local industrial waste, if found suitable for lightweight concrete, can be economically utilized.

- The reduction in weight of concrete helps easy removal, transport and erection of precast products.

- The use of lightweight concrete results in the reduction of cost to the extent of about 30 to 40 percent.

- The lightweight concrete doesn’t present special problems with respect to freezing and thawing. It is due to the fact that the larger pores in aggregate are unlikely to become saturated, provided the cement paste is protected by air entrainment.

- The lightweight concrete has comparatively less tendency to spall. Hence, its fire resistance is greater as compared to the ordinary concrete.

- The lightweight concrete has generally a lower thermal expansion than ordinary concrete.

- The sound absorption of lightweight concrete is good because of the fact that the air-borne sound energy is converted into heat in the minute channels of the concrete. The sound absorption coefficient of the lightweight concrete is nearly twice than that of the ordinary concrete.

Disadvantages of lightweight concrete

The only drawback of lightweight concrete is that the depth of carbonation i.e. the depth within which corrosion can occur under suitable conditions is nearly twice than that of normal concrete. Hence, special care will have to be taken to provide sufficient cover to the reinforcement of the lightweight structures to grant protection against corrosion.