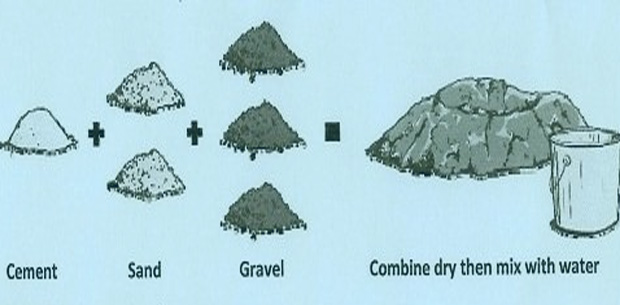

We all know that on mixing cement with sand, stone/aggregates and water, a paste will form which can be used to bind the building materials together. This paste is also called as concrete. The strength of this concrete mix is determined by the proportion on which these cement, sand, stones or aggregates are mixed. There are various grades of concrete available in the market based on these ratios. Some of them are: M10, M20, M30, M35, etc. So, what really does M10 or M20 mean or represent.

“M” stands for “mix”. Mix represents concrete with designated proportions of cement, sand and aggregate. And the number following “M” represents compressive strength of that concrete mix in N/mm2 after 28 days. For example, for M20 grade of concrete mix, its compressive strength after 28 days should be 20 N/mm2.

You can also watch our video here: Video on concrete mix ratio of various grades of concrete

Concrete mix ratio table

Here is the standard chart table showing various grades of concrete mix design along with their respective ratios of cement, sand and aggregates required.

| Grades of Concrete | Ratios of Concrete mix design (Cement:Sand:Aggregate) |

| M5 | 1:5:10 |

| M7.5 | 1:4:8 |

| M10 | 1:3:6 |

| M15 | 1:2:4 |

| M20 | 1:1.5:3 |

| M25 | 1:1:2 |

| M30 | 1:0.75:1.5 |

| M35 | 1:0.5:1 |

| M40 | 1:0.25:0.5 |

As you can see in the table above, volume of sand is always kept half of that of aggregates in these standard mix designs. You can measure and maintain these ratios by using buckets or some other standard cubes which could be easily used throughout the project. It is necessary to maintain consistency in each and every concrete mix prepared during the entire project. It is one of the important job of site engineer/supervisor to inspect and enforce it.

Water content ratio in concrete mix

Besides water content also largely determine the strength & workability of concrete. Greater the amount of water, higher will be the workability of concrete (more fluid) however it reduces the strength of concrete. But if you keep water too low, workability of water will also reduce. Therefore, it will be difficult to place such concrete in the structure. Amount of water required may vary for same volume of concrete for various grades of concrete. Hence, a balance has to be found in the construction site during concrete mixing.