The word ‘coffer’ means a casket, chest or trunk. A cofferdam is a temporary structure built to enclose an area for excavation of foundation. Coffer dams are designed & placed when the size of excavation is very large and sheeting and bracing system becomes difficult or uneconomical. Coffer dams are generally required for foundations of structures, such as bridge piers, docks, locks, and dams, which are built in open water. These are also used for underlying foundations on open land where there is a high ground water table. A coffer dam generally consists of a relatively impervious wall built around the periphery of the proposed excavation to prevent the flow of water into the excavation to prevent the flow of water into the excavation so that the foundation may be laid in dry condition.

Types of cofferdams

Following are the different types of cofferdams commonly used in practice:

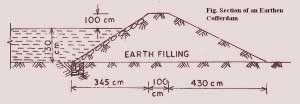

Earth cofferdam

These are the simplest type of cofferdams well-adapted to depths of water upto 3 m. Earth embankments are constructed around the area to be dewatered. The earth coffer dams are built of local soils, preferably fine sand. These usually have a clay core or a vertically driven sheet piling in the middle. The upstream slope of the bank is covered with a rip rap. A successful coffer dam need not be completely watertight. For reason of economy, it is not possible to make it watertight and hence some seepage of water into the excavation is usually tolerated. The water collected is pumped out of the excavation. The embankment should be provided with a minimum free board of 1 m to prevent overtopping by waves. Sand-bag coffer dams are used in an emergency.

Rockfill cofferdam

Rockfill coffer dams made of rockfill are sometimes used to enclose the site to be dewatered. These are permeable and are usually provided with an impervious membrane of soil to reduce seepage. The crest and the upper part of the impervious membrane are provided with rip rap to provide protection against wave action. Overtopping doesn’t cause serious damage in case of rockfill coffer dams. The slopes of a rockfill cofferdam can be made as steep as 1 horizontal to 1.5 vertical.

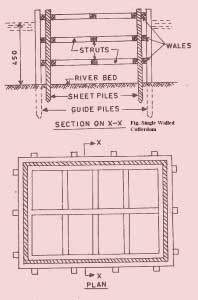

Single sheet pile cofferdam

These are generally used to enclose small foundation sites in water for bridges at a relatively shallow depth. In this type of coffer dams, there is a single row of cantilever sheet piles. The piles are sometimes heavily braced. Joints in the steet piles are properly sealed. This type of coffer dams are suitable for moderate-flow velocities of water and for depth upto 4 m. The depth of penetration below ground surface is about 0.25h for coarse sand and gravels, 0.5h for dine sand and 0.85h for silts, where h is the depth of water. Sometimes single-sheet coffer dams are provided with earth fills on one or both sides to increase the lateral stability. The figure of single sheet pile cofferdam is shown on the right.

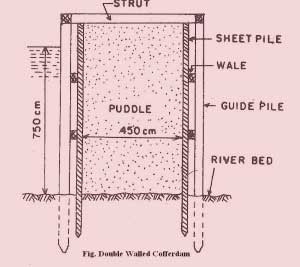

Double-wall Sheet piling cofferdam

These dam consists of two straight, parallel vertical walls of sheet piling, tied to each other and the space between walls filled with soil. The width between the parallel piles is empirically set as (h/2 + 1.5m); where h is height of water. Double-wall sheet piling coffer dams higher than 2.5m should be strutted. Sometimes, an inside berm is provided to keep the phreatic line within the berm.

The fill material should have a high coefficient of friction and unit weight so that it performs as a massive body to give the coffer dam stability against sliding and overturning. Suitable measures should be adopted to reduce the uplift on the coffer dam. This is generally done by driving the sheet piling on the upstream as deep as possible.

The double-wall sheet piling coffer dam has the advantage of having less leakage than that in a single-wall coffer dam. These coffer dams are suitable upto a height of 10m.

Braced cofferdam

A braced coffer dam is formed by driving two rows of vertical sheeting and bracing with wale and struts. These are similar to sheeting and bracing system with one basic difference that braced cuts are required for excavations in dry areas whereas braced coffer dams are used to isolate a working area surrounded by water. The braced coffer dams are susceptible to flood damage.

Braced cofferdams are sometimes used as land coffer dams to prevent ground from entering the foundation pile pit on land and to support the soil so as to prevent cave in. After the pit is dewatered, the structure is concreted. When concreting has been completed above the water level, the coffer dam is removed.

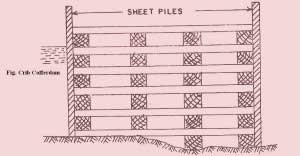

Cellular cofferdam

This is constructed by driving sheet piles of special shapes to form a series of cells. Te cells are interconnected to form a watertight wall. These cells are filled with soil to provide stabilizing force against lateral pressure. Basically, there are two types of cellular coffer dams that are commonly used:

-

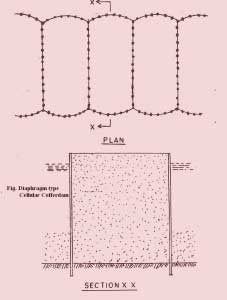

Diaphragm type cellular cofferdam Diaphragm Type: This type of cellular cofferdam consists of circular arcs on the inner and outer sides which are connected by straight diaphragm walls. The connection between the curved parts and the diaphragms are made by means of a specially fabricated Y-element. The coffer dam is thus made from inter-connected steel sheet piles. The cells are filled with coarse-grained soils which increase the weight of the cofferdam and its stability. The leakage through the coffer dam is also reduced.

To avoid rupture of diaphragms due to unequal pressure on the two sides, it is essential to fill all the cells at approximately the same rate. One advantage of the diaphragm type is that the effective length of the cofferdam may be increased easily by lengthening the diaphragm. -

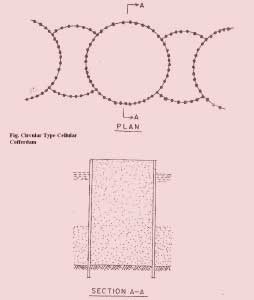

Circular type Cellular cofferdam Circular Type: It consists of a set of large diameter main circular cells interconnected by arcs of smaller cells. The walls of the connecting cells are perpendicular to the walls of the main circular cells of large diameter. The segmental arcs are joined by special T-piles to the main cells.

The circular type cellular cofferdams are self-sustaining, and therefore independent of the adjacent circular cells. Each cell can be filled independently. The stability of such cells is much greater as compared with that of the diaphragm type. However, the circular cells are more expensive than the diaphragm type, as these require more sheet piles and greater skill in setting and driving the piles. Because the diameter of circular cells is limited by interlock tension, their ability to resist lateral pressure due to high heads is limited.